Masonry Support

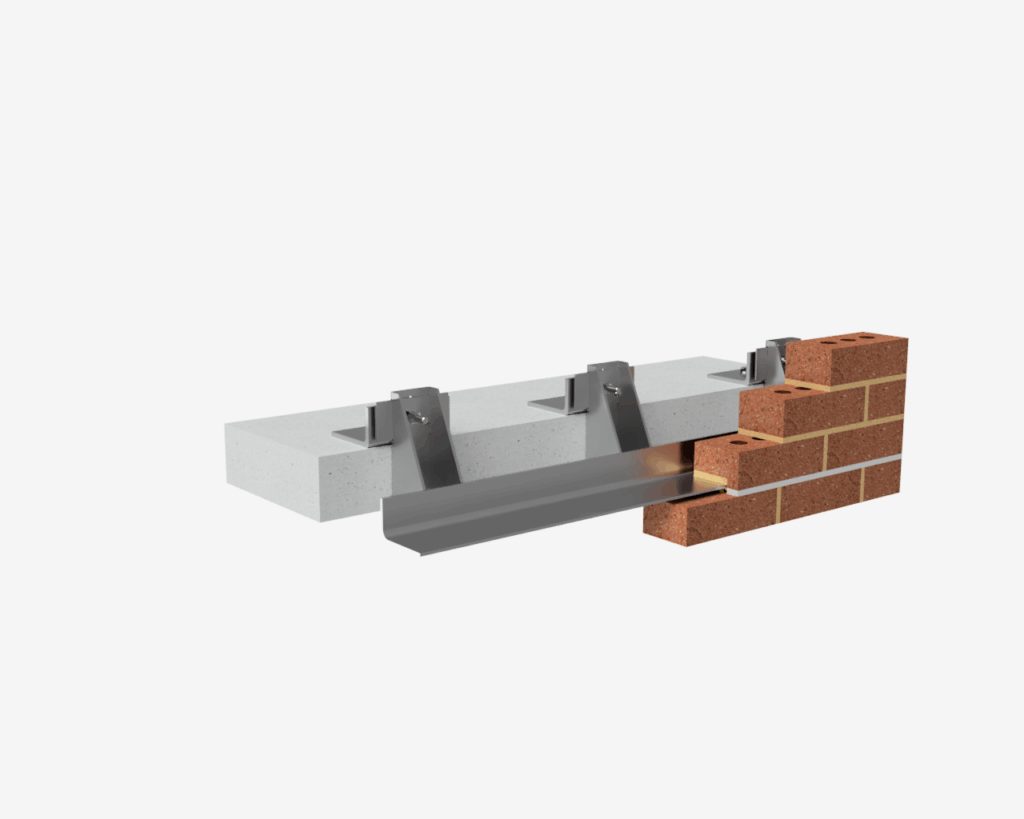

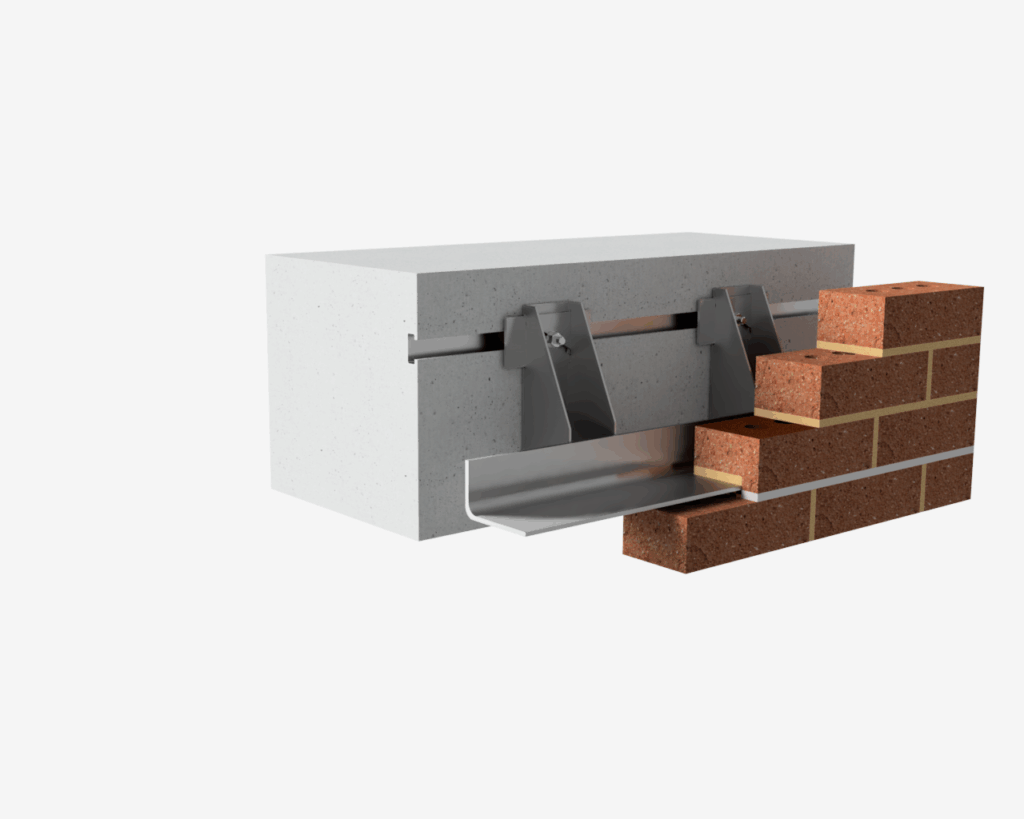

These systems consist of bracketed angles precision-welded and tailored to suit varying load, cavity, and fixing conditions. Designed to integrate seamlessly with structural interfaces, they deliver robust performance across a wide range of applications.

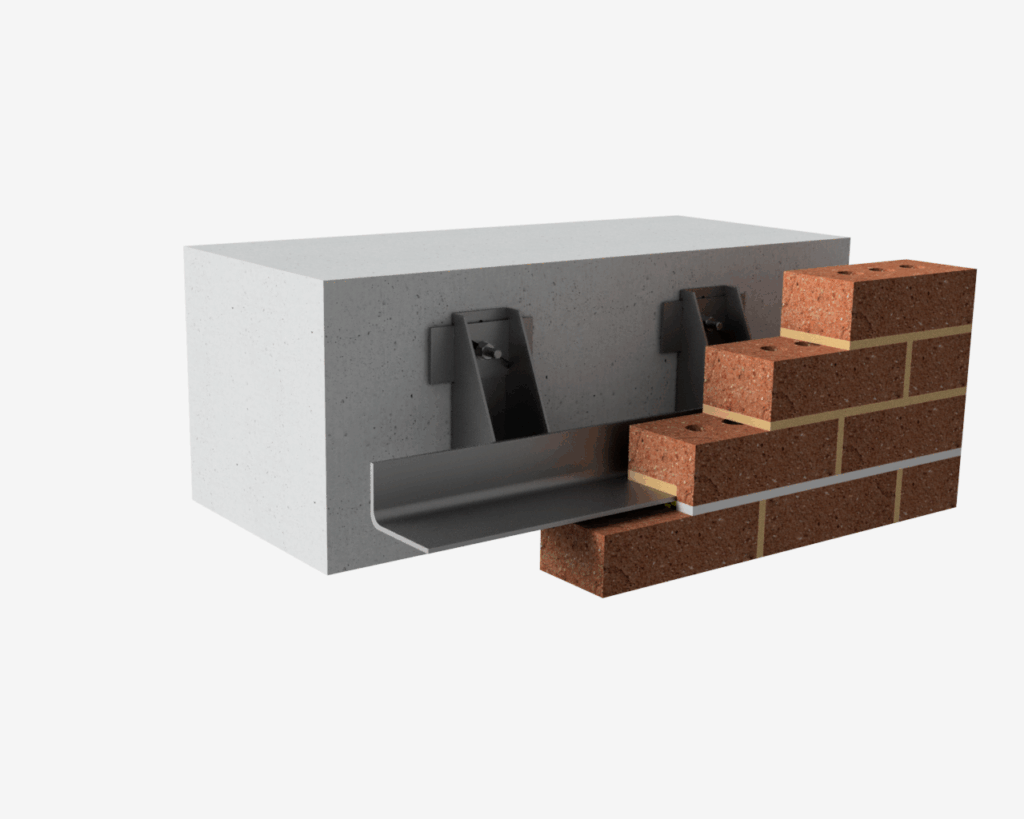

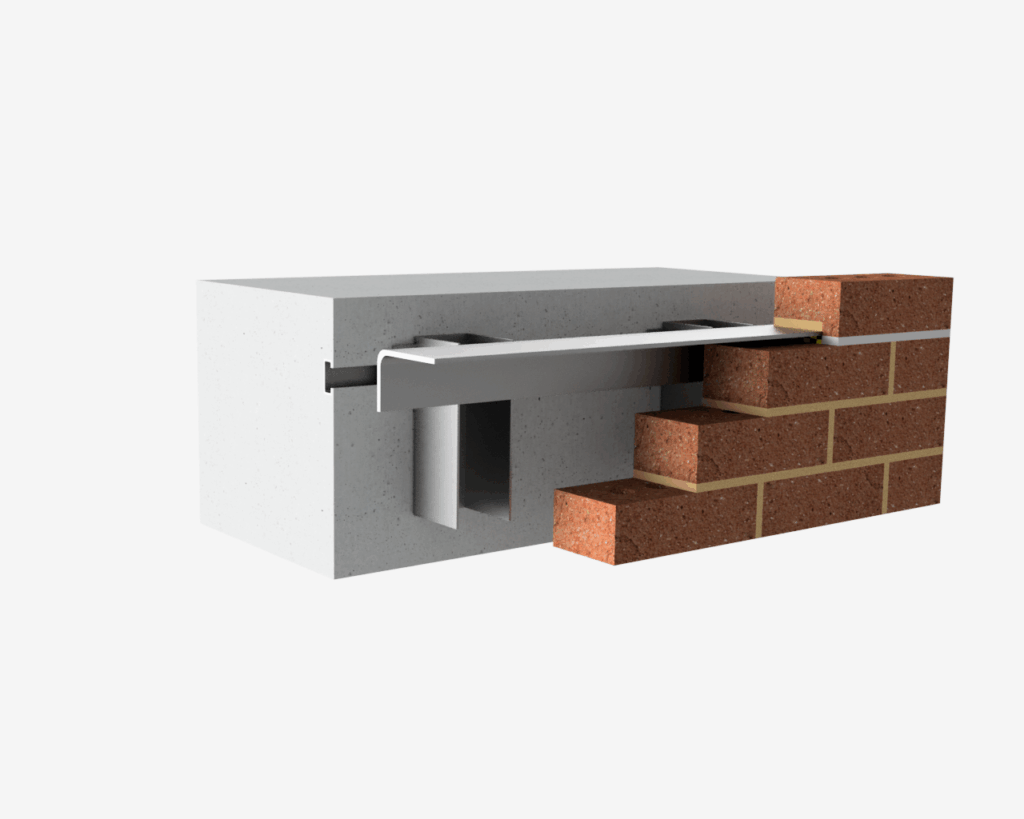

Welded Masonry Support Systems

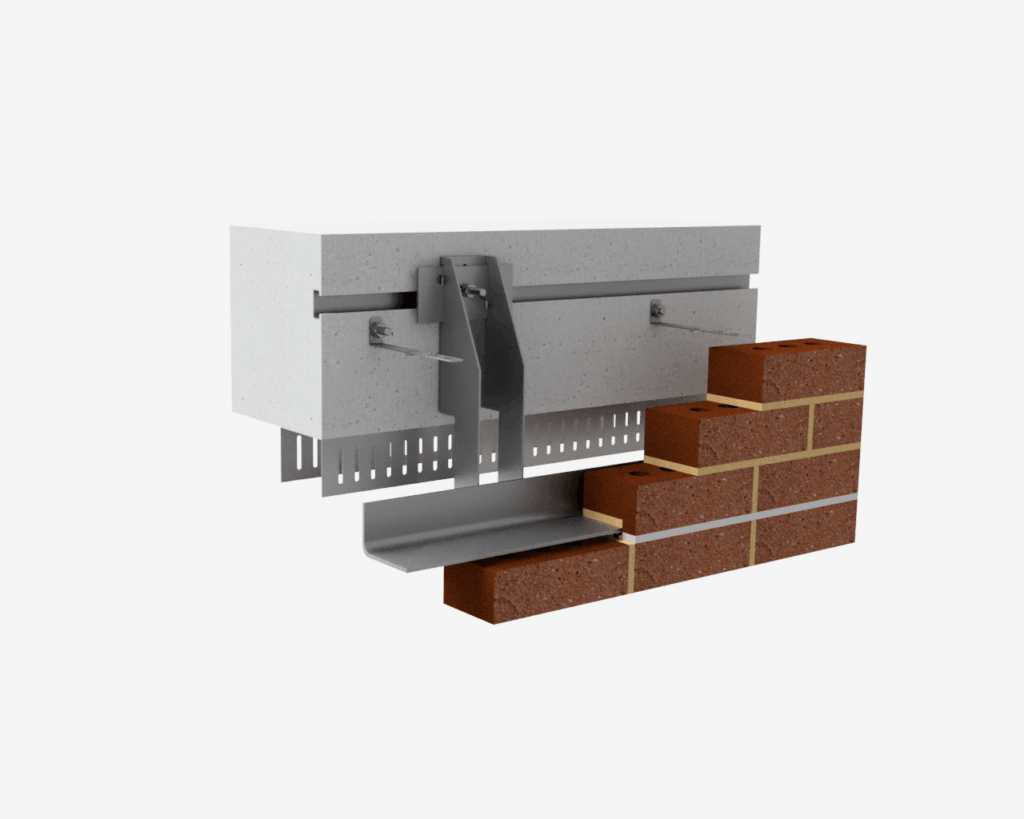

Each Birtley welded masonry support system is custom-designed and fabricated to meet precise project-specific requirements, ensuring structural integrity and seamless integration across concrete and steel substrates. These systems comprise bracketed angles welded to specification and configured for reliable onsite installation, accommodating diverse load paths, cavity widths, and structural fixing scenarios.

Masonry Support

Every Birtley masonry support system is engineered to suit specific project conditions, with bracket spacing, projection, and cavity sizing optimized to withstand designated masonry and wind loads. Fixing systems—including cast-in channels, top cleats, and direct anchors—are selected and detailed to suit substrate and tolerance constraints.

Fixtures, fittings, and resin anchors are supplied as part of a complete system offering, and each bracket system is delivered fully quality-checked, traceable, and install-ready—reducing on-site risk, improving program certainty, and aligning with regulatory compliance for structural interfaces.

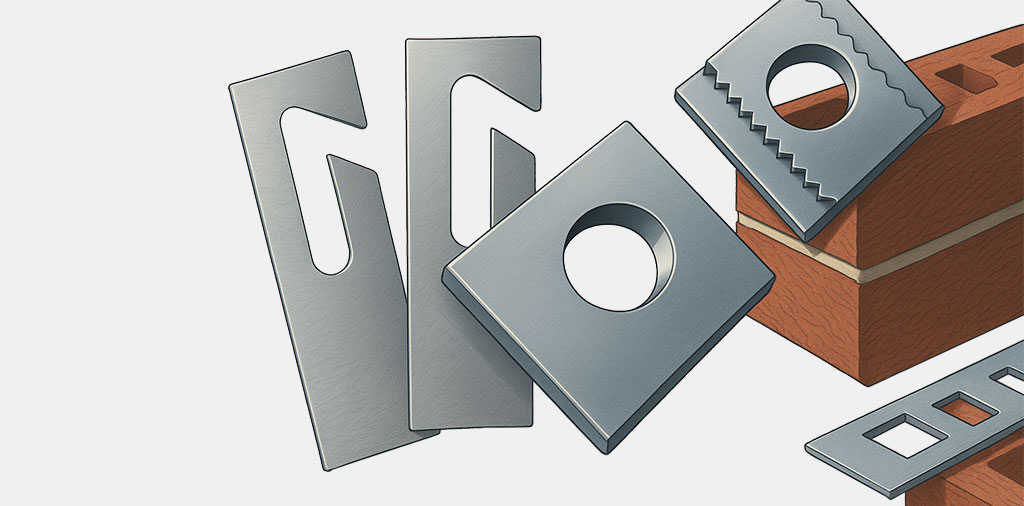

Accessories & Fixings

We can also support with all of your Accessories and Fixing requirements for your projects

Enquire now